CONTINUOUS HAULAGE SYSTEMS

For over twenty years, Prairie Machine’s line of Continuous Haulage equipment has been an integral component in the most productive soft rock mines across the world. Spearheaded by the Flexiveyor, this customizable product line works in conjunction with any mining equipment infrastructure to provide a safe, automated, and continuous flow of ore, no matter the environment.

Our explosion proof Flexiveyor is MSHA certified for use in underground coal mines. This certification underlines our commitment to providing safe, effective mining solutions, no matter the situation.

FLEXIVEYOR

The customizable Flexiveyor works in conjunction with any mining machine to provide a safe, automated, and continuous flow of ore.

The Flexiveyor is designed to continuously convey ore and tram around corners as sharp as 50⁰ with minimal operator supervision.

The Miner Follower system allows the Flexiveyor to automatically follow any mining machine through all corners of the mine, all while maintaining a throughput rate of up to 1200 tons of ore per hour.

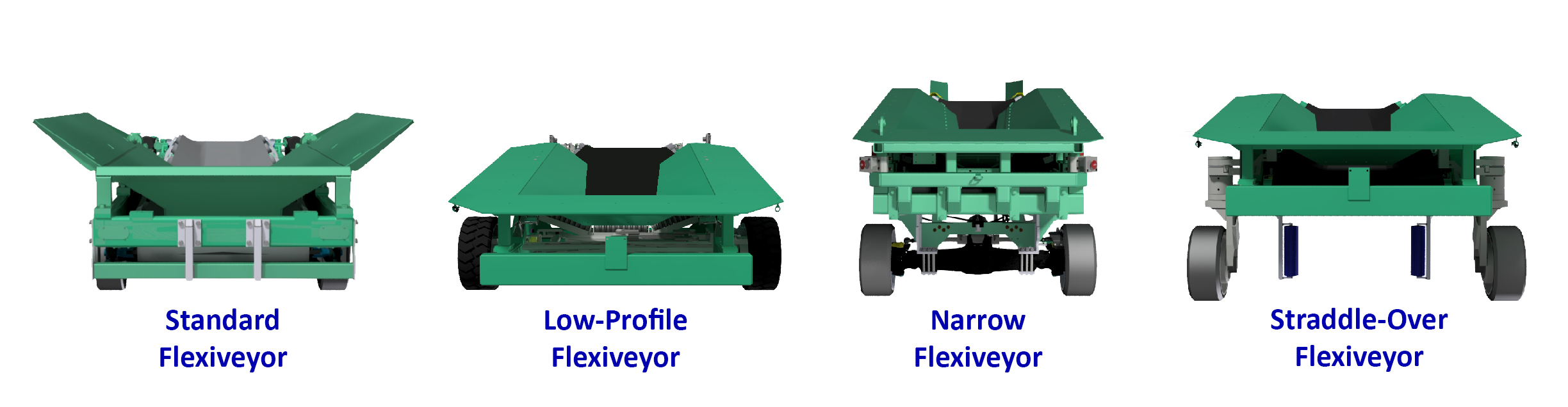

Available in multiple configurations, the Flexiveyor is custom to contain an endless number of individual conveyor cars.

- The tried and tested Standard Flexiveyor is the ideal haulage solution in conventional mining environments.

- The Low-Profile Flexiveyor brings the same continuous haulage power to mines with limited access.

- The compact Narrow Flexiveyor integrates seamlessly into mines with restricted entry ways and work areas.

- With greater ground clearance, the Straddle-Over Flexiveyor is ideal for narrow mines with reduced access or with unstable ground conditions.

| Series | Standard | Low-Profile | Narrow |

Straddle-Over |

|---|---|---|---|---|

| Height | 7 ft | 4.25 ft | 7.75 ft | 7.50 ft |

| Height | 2.25 m | 1.25 m | 2.25 m | 2.25 m |

| Width | 8.25 ft | 8.25 ft | 6.25 ft | 8.25 ft |

| Width | 2.50 m | 2.50 m | 2 m | 2.50 m |

| Length* (Of a 23-Car Flexiveyor) |

460 ft | 460 ft | 460 ft | 460 ft |

| Length* (Of a 23-Car Flexiveyor) |

140 m | 140 m | 140 m | 140 m |

| Ground Clearance | 8 in | 6 to 10 in | 6.75 in | 27 in* (Customizable) |

| Ground Clearance | 20 cm | 15 to 25 cm | 16.25 cm | 68.50 cm* (Customizable) |

| Tramming Speed | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min |

| Tramming Speed | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min |

| System Voltage | 600-Volt /1,000-Volt |

600-Volt /1,000-Volt |

600-Volt /1,000-Volt |

600-Volt /1,000-Volt |

| Power Output* (Of a 23-Car Flexiveyor) |

320 hp | 320 hp | 320 hp | 320 hp |

| Power Output* (Of a 23-Car Flexiveyor) |

238 kW | 238 kW | 238 kW | 238 kW |

| Throughput | Up to 1,200 ton/hr |

Up to 1,200 ton/hr |

Up to 800 ton/hr |

Up to 1,200 ton/hr |

| Throughput | Up to 1,088 tonne/hr |

Up to 1,088 tonne/hr |

Up to 725 tonne/hr |

Up to 1,088 tonne/hr |

BELTLINE CLEAN-UP FLEXIVEYOR

The Beltline Clean-Up Flexiveyor ensures that no ore goes to waste.

The versatile Beltline Clean-Up Flexiveyor is engineered to follow any mining machine and to collect ore from the floor behind it and to collect any run-off from below a site's stationary conveyor belt system.

Each of the 3 cars found in this Flexiveyor system has independent steering and conveyor belt systems. The Beltline Clean-Up Flexiveyor can be turned to convey in any position and provides maximum ore output with minimal operator supervision.

| Series | Standard |

|---|---|

| Maximum Operating Height | 11.25 ft |

| Maximum Operating Height | 3.50 m |

| Tramming Height | 8.25 ft |

| Tramming Height | 2.50 m |

| Width | 12.25 ft |

| Width | 3.75 m |

| Length | 49.75 ft |

| Length | 15.25 m |

| Ground Clearance | 6 in |

| Ground Clearance | 15 cm |

| Tramming Speed | 0 to 20 ft/min |

| Tramming Speed | 0 to 6 m/min |

| System Voltage | 600V / 1,000V |

| Power Output | 80 hp |

| Power Output | 59.50 kW |

| Throughput | Up to 600 ton/hr |

| Throughput | Up to 544 tonne/hr |

| PLC | Siemens |

SAFETY

Prairie Machine's continuous haulage equipment is engineered with safety as its primary concern.

Automated and Manual Emergency Stops ensure the safety of the Flexiveyor and Flex Bridge operator and surrounding mine personnel.

An optional Operator Proximity System makes sure that mine personnel are away from any hazardous zones during operation.

The Fire Suppression System combats any overheating caused by the hydraulic components of the Flexiveyor or Flex Bridge.