CONTINUOUS BORING SYSTEMS

For over twenty-five years, the most industrious potash, salt, and trona mines world-wide have utilized Prairie Machine’s Continuous Boring equipment to meet their high production demands. The Continuous Boring line can be paired with the Prairie Machine Flexiveyor, the Prairie Machine Auxiliary Equipment line, or any conveyor belt system to produce high quantities of ore with zero stoppage time.

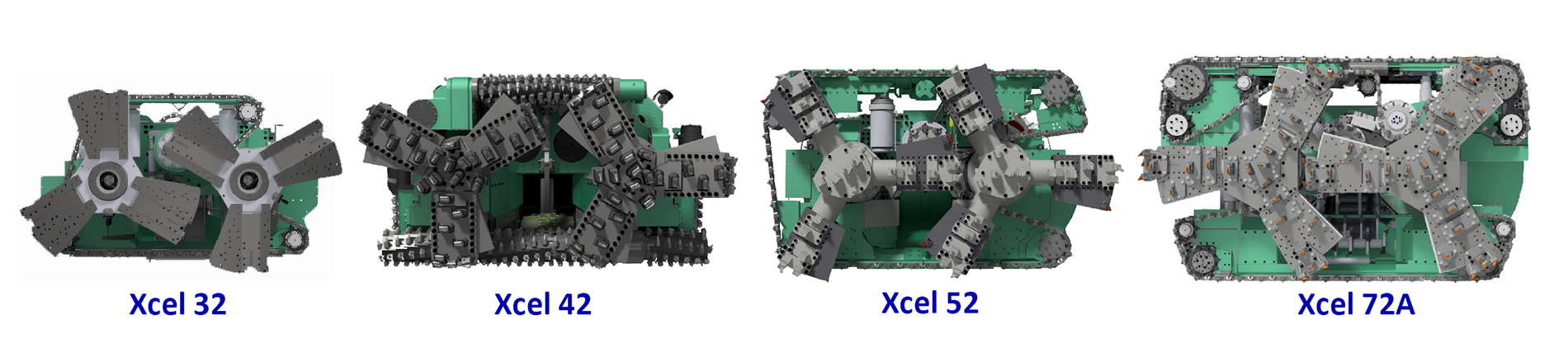

COMPARE CONTINUOUS BORING MINERS

Xcel Continuous Boring Miners are custom-built to meet the demands of any mine.

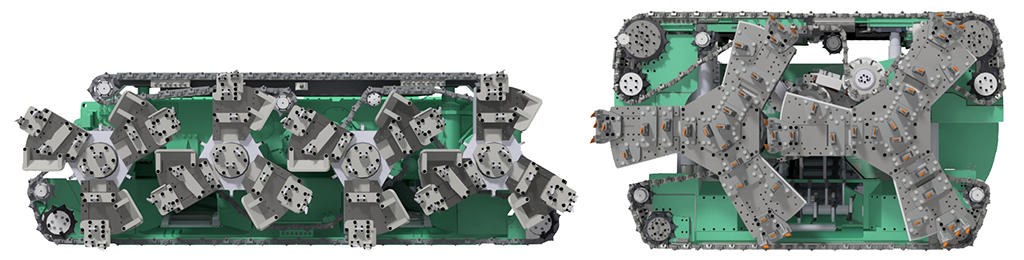

Working in conjunction with its two or four cutting rotors, the cutting chain system ensures that the Xcel Continuous Boring Miner safely produces a uniform cutting path during mine development and production.

The Xcel 2-Rotor Continuous Boring Miner's optional horizontal and vertical cutting drums are engineered to provide the same consistent cutting profile while offering enhanced durability when cutting especially abrasive materials.

| Series | Xcel 44 | Xcel 32 | Xcel 42 | Xcel 52 | Xcel 72A |

|---|---|---|---|---|---|

| Number of Cutting Rotors | 4 | 2 | 2 | 2 | 2 |

| Cutting Rotor Motor Output | 298 kW at 1,200 rpm |

224 kW at 1,185 rpm |

298 kW at 1,185 rpm |

373 kW at 1,185 rpm |

522 kW at 1,185 rpm |

| Cutting Rotor Motor Output | 400 hp at 1,200 rpm |

300 hp at 1,185 rpm |

400 hp at 1,185 rpm |

500 hp at 1,185 rpm |

700 hp at 1,185 rpm |

| Tramming Speed | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min |

| Tramming Speed | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min |

| Cutting Profile Area | 203 to 206 ft² | 100 ft² | 129 ft² | 182 ft² | 229 ft² |

| Cutting Profile Area | 61.75 to 62.75 m² | 30.50 m² | 39.25 m² | 55.50 m² | 39.75 m² |

| Maximum Cutting Width | 25.75 to 26 ft | 14 ft | 16 ft | 18.25 ft | 20 ft |

| Maximum Cutting Width | 7.75 to 8 m | 4.25 m | 5 m | 5.50 m | 6 m |

| Maximum Cutting Height | 8.25 to 8.50 ft | 8.25 ft | 8 ft | 11.00 ft | 12.00 ft |

| Maximum Cutting Height | 2.50 to 2.60 m | 2.50 m | 2.50 m | 3.50 m | 3.75 m |

| Tramming Height | 7 to 7.50 ft | 7 ft | 7.50 ft | 9.50 ft | 10.50 ft |

| Tramming Height | 2 to 2.25 m | 2 m | 2.25 m | 3 m | 3.25 m |

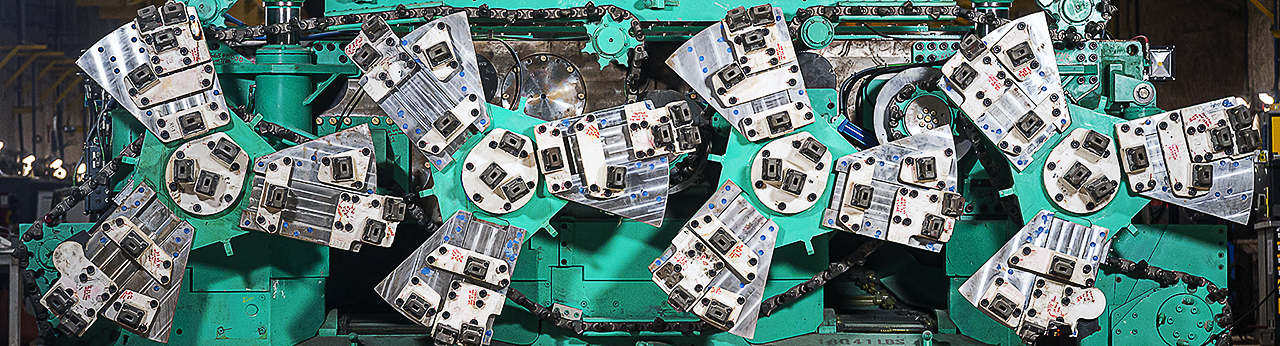

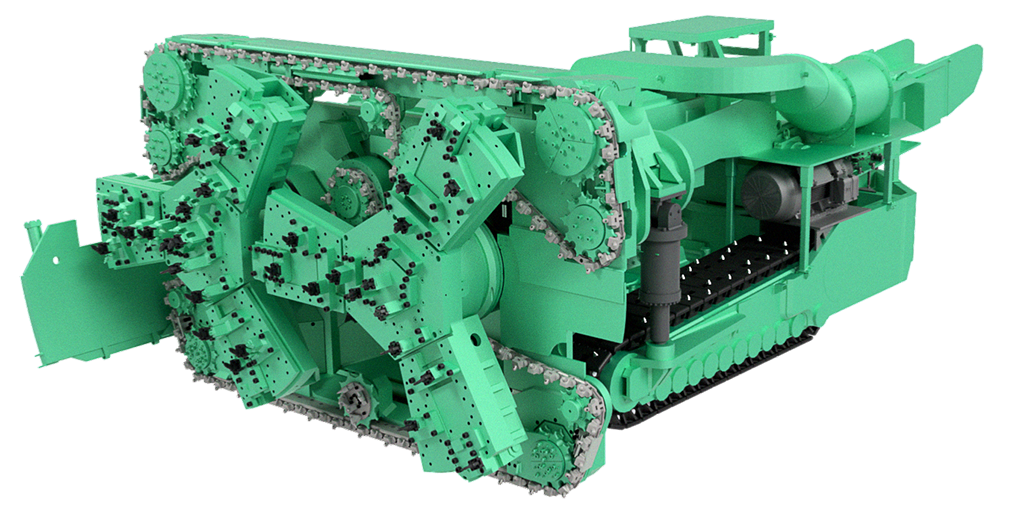

XCEL 4-ROTOR CONTINUOUS BORING MINER

The Xcel 4-Rotor Continuous Boring Miner has produced millions of tonnes of ore over the past twenty-five years.

The broad, low-profile Xcel 4-Rotor Continuous Boring Miner is equipped for high-quantity production in sites with spatial restrictions. Its four cutting rotors and horizontal cutting chain system work together to form a flat, smooth cutting channel, no matter the environment. The design of the Xcel 4-Rotor Continuous Boring Miner allows it to cut and convey ore to a site's conveyor belt system or to the Prairie Machine Flexiveyor while continuously tramming forward.

A vital component in some of the most productive potash, salt, and trona mines across the globe, Prairie Machine’s Xcel 4-Rotor Continuous Boring Miner is engineered to safely and proficiently meet the highest production demands.

| Series | Xcel 44 |

|---|---|

| Number of Cutting Rotors | 4 |

| Cutting Rotor Motor Output | 400 hp at 1200 rpm |

| Cutting Rotor Motor Output | 298 kW at 1200 rpm |

| Tramming Speed | 0 to 20 ft/min |

| Tramming Speed | 0 to 6 m/min |

| Cutting Profile Area | 203 to 206 ft² |

| Cutting Profile Area | 18.75 to 19.25 m² |

| Maximum Cutting Width | 25.75 to 26 ft |

| Maximum Cutting Width | 7.75 to 8 m |

| Maximum Cutting Height | 8.25 to 8.50 ft |

| Maximum Cutting Height | 2.50 to 2.60 m |

| Tramming Height | 7.00 to 7.50 ft |

| Tramming Height | 2 to 2.25 m |

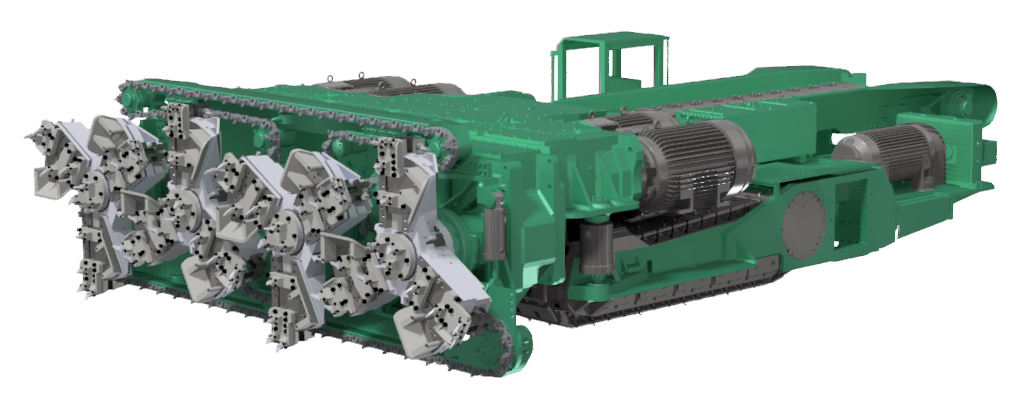

XCEL 2-ROTOR CONTINUOUS BORING MINER

The Xcel 2-Rotor Continuous Boring Miner is engineered for seamless integration into any mining operation.

Utilized in everything from initial development to producing ore in the largest of mine rooms, Prairie Machine’s Xcel 2-Rotor Continuous Boring Miner is an adaptable, efficient, and safe way to meet your site’s specific needs.

- The Xcel 32 is engineered to facilitate mine development and mine panel maintenance in sites with any spatial restrictions.

- The versatile Xcel 42 is MSHA-approved for safe operation in exceptionally hazardous mining environments.

- The mid-sized Xcel 52 is purpose built to meet the production needs of a conventional mine site.

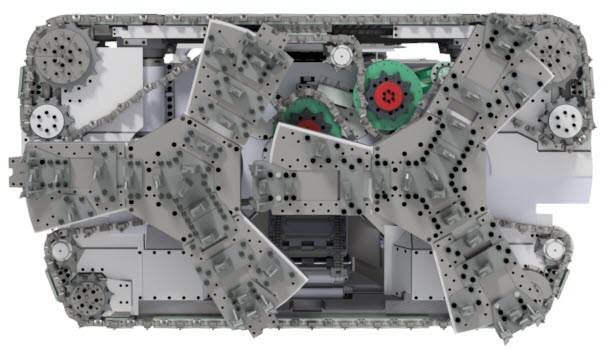

- The Xcel 72A is Prairie Machine’s largest and most powerful Continuous Boring Miner to date and is equipped to handle the production needs of large-scale mining operations.

| Series | Xcel 32 | Xcel 42 | Xcel 52 | Xcel 72A |

|---|---|---|---|---|

| Number of Cutting Rotors | 2 | 2 | 2 | 2 |

| Cutting Rotor Motor Output | 300 hp at 1,185 rpm |

400 hp at 1,185 rpm |

500 hp at 1,185 rpm |

700 hp at 1,185 rpm |

| Cutting Rotor Motor Output | 224 kW at 1,185 rpm |

298 kW at 1,185 rpm |

373 kW at 1,185 rpm |

522 kW at 1,185 rpm |

| Tramming Speed | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min | 0 to 20 ft/min |

| Tramming Speed | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min | 0 to 6 m/min |

| Cutting Profile Area | 100 ft² | 129 ft² | 182 ft² | 229 ft² |

| Cutting Profile Area | 9.25 m² | 12 m² | 17 m² | 21.25 m² |

| Maximum Cutting Width | 14 ft | 13 ft | 18.25 ft | 20 ft |

| Maximum Cutting Width | 4.22 m | 4.75 m | 5.52 m | 6 m |

| Maximum Cutting Height | 8.25 ft | 8 ft | 11 ft | 12 ft |

| Maximum Cutting Height | 2.50 m | 2.50 m | 3.25 m | 3.75 m |

| Tramming Height | 7 ft | 7.50 ft | 9.50 ft | 10.50 ft |

| Tramming Height | 2 m | 2.25 m | 3 m | 3.25 m |

AUXILIARY CONTINUOUS BORING EQUIPMENT

XCEL TORQUE LIMITER

The custom Xcel Torque Limiter extends the lifespan of the trim chain drive system and reduces downtime brought on by unpredictable ground conditions. The Xcel Torque Limiter is a standard option on all Xcel Miners and can be retrofitted to any Continuous Boring Miner to protect the machine's trim chain, trim chain drive pinions, and associated trim chain system components from damage caused by extreme torque during operation.

Traditional machine safety systems, such as the shear pins, often suffer from a lack of reliability and consistency. When shear pins break too easily, sites will experience unnecessary downtime brought on by machine repair. When shear pins fail to break after being subjected to excessive torque, the Boring Miner's drive components can incur serious damage and can become a potential risk to the operator and surrounding mine personnel. A properly functioning shear pin system has its own set of limitations. Any time an overtorque event occurs, maintenance staff must replace the shear pins, putting them in a potentially hazardous situation. The Xcel Torque Limiter requires zero maintenance following an overtorque event, saving the downtime and inherent risk associated with machine maintenance.

The Xcel Torque Limiter is calibrated according to a custom-defined torque range and is integrated into the Continuous Boring Miner's programmable logic controller (PLC). Should the Boring Miner's cutting components be subjected to excessive force, the Xcel Torque Limiter automatically slips to stop the machine, reduce the load, and preserve vital machine components. The PLC alerts the operator of any slips to allow them to make operating adjustments as necessary.

XCEL CAROUSEL BOLTER

The Xcel Carousel Bolter is mounted to an Xcel Continuous Boring Miner to facilitate mining and rock support operations without the need for a standalone piece of rock support equipment. A drill steel, eight roof bolts, and eight associated resin tubes are all housed within the onboard carousel to ensure that support bolts are installed as efficiently and as securely as possible.

Learn More About the Xcel Carousel Bolter

SAFETY

Prairie Machine's Continuous Boring Miners are engineered with safety as their primary concern.

Automatic machine interlocks and manual emergency stop systems ensure the safety of the Boring Miner operator and of the surrounding mine personnel.

The heartbeat monitoring system ensures proper communication and function across multiple Boring Miner components

The optional methane monitoring system issues important warnings and prevents the Boring Miner from operating in a dangerous atmosphere.