Posted June 4th, 2024

Innovative Commissioning Process Supports Global Sales

When the Mosaic Company, one the world’s leading integrated producer of concentrated phosphate and potash, needed to expand their operations in Brazil, Prairie Machine was able to deliver solutions from more than 10,000 kilometers away.

This long-distance partnership was set up several years ago when Mosaic's global procurement groups came together to meet and learn from each other. The Brazilian representatives expressed frustration with their equipment vendor, who required increasingly long lead times to build or repair equipment and often struggled to supply the necessary parts.

In response, the Mosaic Saskatchewan representatives, who had been loyal customers of Prairie Machine for decades, suggested their Brazilian counterparts contact us to see if we could help.

A Common Language

Mosaic Saskatchewan recently facilitated introductions between the company's Brazil operations and Prairie Machine. From the outset, we listened attentively to understand the specific challenges Mosaic Brazil was facing and at once began addressing them. One key advantage we had was our team of three native Portuguese-speaking Brazilians, including members of our sales and technical teams. This linguistic capability allowed Mosaic Brazil to discuss their timelines and operating requirements in their native language, making the entire process significantly smoother and more efficient.

Prairie Machine’s technical sales team at Mosaic Fertilizantes in Brazil

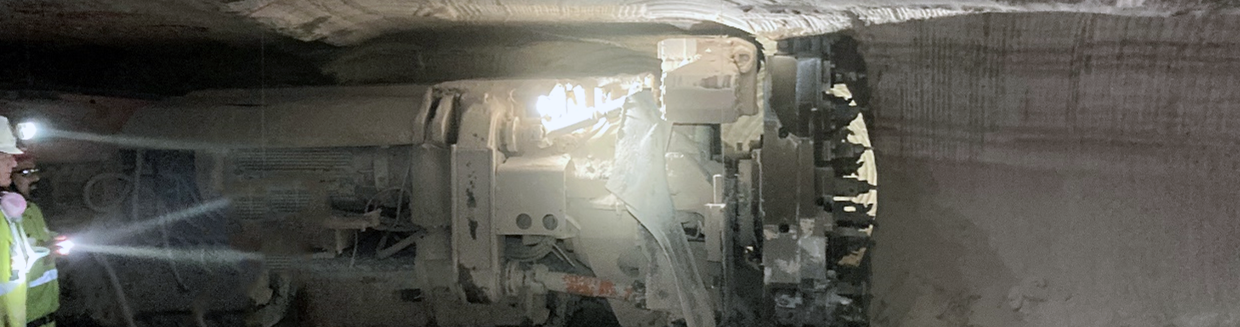

The team's machinery had been customized to the unique needs of their operations, so Prairie Machine made an on-site visit to examine the machines and perform an extra layer of due diligence to ensure the parts we fabricated could accommodate the modifications and meet the specs exactly. Taking more care up front resulted in the custom parts reaching the mine faster and performing flawlessly.

Mine Expansion

This positive experience with Prairie Machine opened the door to a deeper relationship three years later when the Brazilian mine decided to increase production capacity, a decision that required them to acquire four additional mining machines. These machines required specific, custom mechanical configurations so that they exactly matched the machines already in operation and could use the common replacement parts.

Based on their previous experience with Prairie Machine and our proven ability to commit to the required level of customization, Mosaic chose us as the partner to service their needs.

Unique Commissioning Process

The vast distance between the location where the machines would be built and the mine site where they would operate inspired us to develop a unique commissioning process to ensure a smooth deployment.

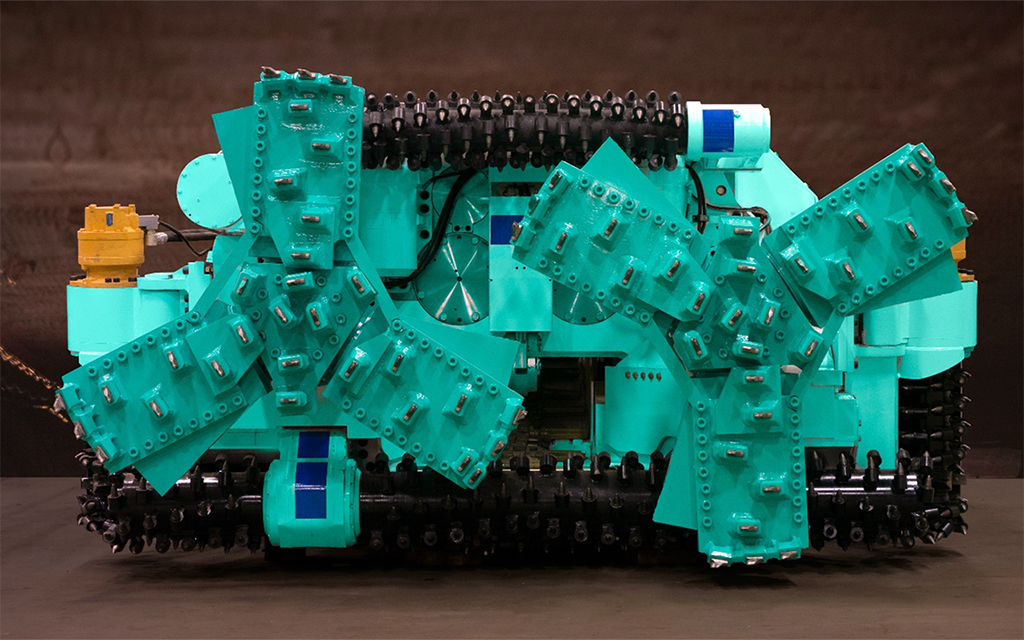

Our technical team decided to fully assemble and power up the first of the four machines at the factory to ensure the machine was fully commissioned and tested prior to being disassembled and shipped to Brazil.

This approach added to the lead time for delivery of the machines, but it saved time and effort in the long run. By troubleshooting and testing the machine in the shop, we forestalled any issues that could delay the deployment of the machines once they reach their destination.

A Blueprint for Global Sales

The enduring success of the relationship with Mosaic's Brazilian operations has proven that Prairie Machine is capable of delivering the same level of responsiveness, reliability, and customization to global clients that we are known for among our Canadian customers.

With a commissioning process that enables us to build, troubleshoot, and fine-tune the performance of our machines before shipping them abroad, we are now ready to fulfill global orders quickly, efficiently, and reliably. We now serve mining customers in Brazil and Mexico, and are forging relationships with potash mines even further afield who need high-quality conventional and battery-powered electric vehicles and equipment for their operations.