Posted March 12th, 2024

Five Decades on, this Partnership Still Sparks Innovation

The connection between Nutrien and Prairie Machine was forged nearly fifty years ago. But there is nothing old-fashioned about the mining innovations that this enduring partnership continues to inspire. As Nutrien's network of potash mines have evolved over the years, Prairie Machine has been there to ensure they had the equipment they needed to scale up fast enough to keep pace with their strategic plans. Just as important, we have helped them discover new ways to enhance the safety and efficiency of their operations.

A partner in growth

In 2008, Nutrien decided to simultaneously expand all six of its potash mine sites. Putting this ambitious plan into action required an unprecedented variety of equipment to upgrade shaft infrastructure, expand tunnels, and milling operations. Prairie Machine was able to provide continuous boring miners, continuous haulage systems, and a variety of auxiliary mining equipment.

Today, Nutrien is the world’s largest producer of potash and the world's third largest nitrogen fertilizer producer, and we continue to work side by side with the company's mine managers to ensure they have the equipment and servicing they need.

A partner in innovation

Being able to scale up the production of mining equipment to keep pace with Nutrien's extraordinary growth is just one value driver in this long-term partnership. Another, is the close collaboration between the two companies, a collaboration that has resulted in innovations that measurably improve the safety and efficiency of Nutrien's mining operations.

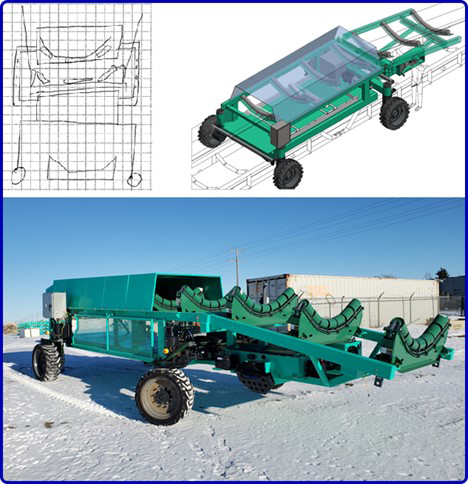

One of these new ideas started as a quick sketch scribbled on the back of a beer coaster by the mine site superintendent during a casual lunch with our staff. He wanted to streamline conveyor infrastructure development processes and develop the mine without interrupting production, by creating a belt cart that would allow his team to continue mining while assembling and installing belt structure. It had never been done before, but as a pioneer in battery-powered mining equipment, we knew that battery electric technology could help improve conventional belt conveyance and continuous haulage.

Our combined expertise in mining equipment and electric technologies turned out to be a winning formula. Working closely with the mine superintendent, we began prototyping, and discovered that by adapting the belt conveyor and powering it with our patented modular-system Rokion battery technology, we could create a belt cart that no longer needed to be plugged into a stationary power source and could be moved around freely.

The result, is a transformative piece of mining equipment that makes daily operations safer, cleaner, and more efficient. And the journey from a beer-coaster doodle-to technical drawings-to completed prototype took less than a year.

Like all innovations co-created by Prairie Machine and its customers, the battery-operated belt cart is designed to deliver value today, and over the long term. We built the unit using components identical to those Nutrien already keeps on hand in their mines, so managing spare parts for new or modified equipment is easy and cost effective.

Moving mining forward

As Prairie Machine’s CEO Kipp Sakundiak puts it, “relationships in the mining industry are built on "battle scars and handshakes." For Prairie Machine, that means being willing to take risks, own our mistakes, and collaborate openly with our customers in the quest for solutions to their toughest problems.”

Nearly fifty years on, Nutrien and Prairie Machine continue to explore ideas that test the bounds of conventional mining, and each partner pushes the other to go further and think differently. The results do not just benefit our customers: they move the entire industry forward, one innovation at a time.