Posted August 17th, 2022

Convey Around a 90-Degree Corner?

Over two decades ago, Prairie Machine was approached with a problem: how do we convey potash around a 90⁰ corner?

By this point, the first generation of Flexiveyors were already facilitating continuous potash haulage operations, but the system was not capable of navigating a corner sharper than 50⁰. Determined to build a solution, Prairie Machine went to work designing what would become the Angle Station.

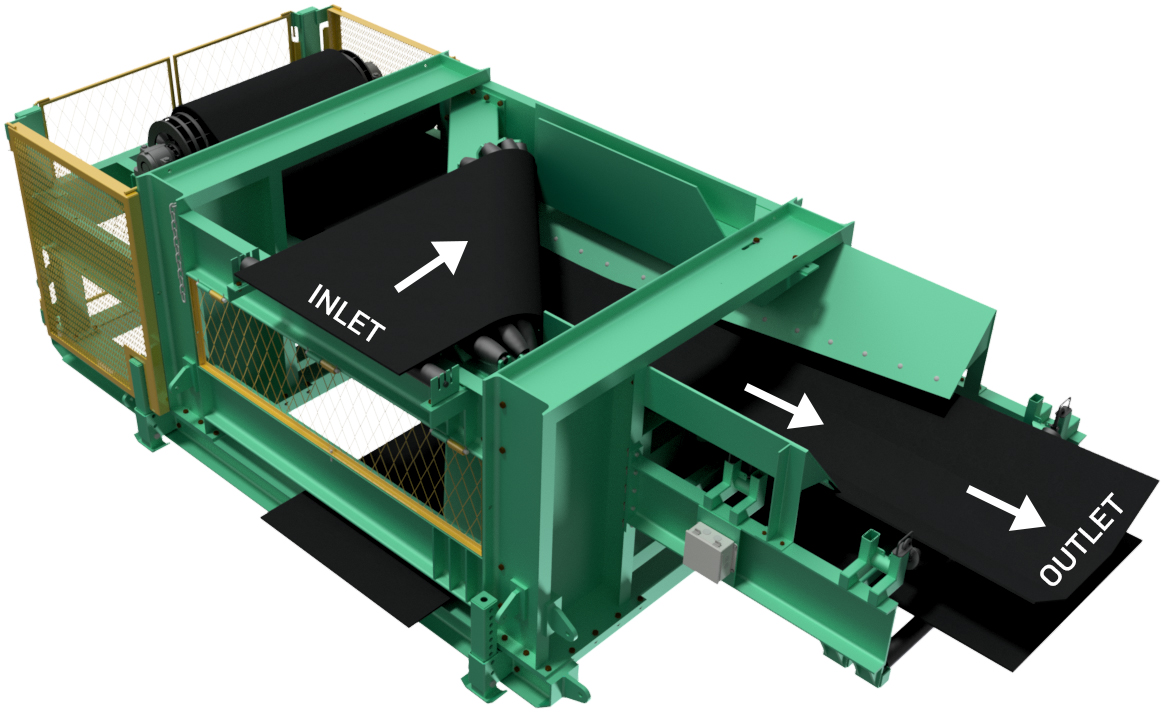

A series of pulleys guide the loaded and return sides of the conveyor belt into and out; the upper pulley structures guide the loaded side of the belt and the lower pulley structures guide the return side of the belt. During operation, the Angle Station transfers ore from the inlet side of the belt to the outlet side of that same belt. Using this equipment and just one conveyor belt, a mine can convey material around a 90⁰ corner.

As with all Prairie Machine equipment, the Angle Station is engineered with safety as its primary concern. The Angle Station is designed to operate automatically, without the need of a dedicated operator. Pulley guards protect mine personnel from all moving parts and conveyor belt detection sensors monitor the loaded and return sides of the belt during operation and halt operation in the event of belt failure.

The Angle Station is one of many examples of Prairie Machine’s goal to build unique solutions to unique problems. With a combination of decades of experience in the underground mining industry and a strong desire to innovate, Prairie Machine is ready to take on any challenge that comes their way.